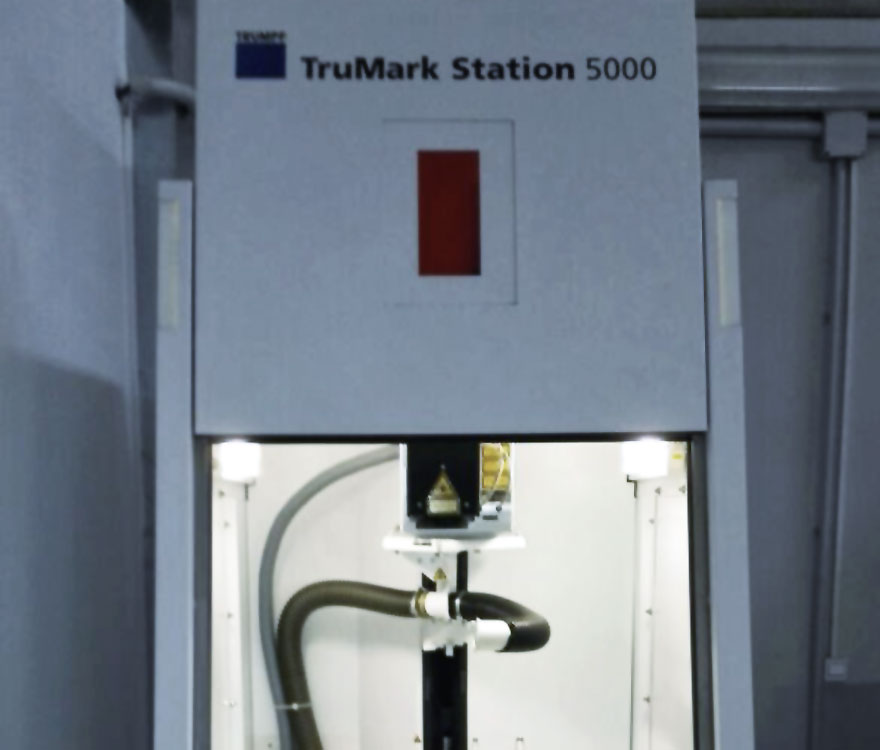

We use a UV marking laser for the surface activation of composite materials used in the aeronautical industry aeronautical industry as a pre-gluing and pre-painting operation.

Since 2012 we have been working on the search for automated treatments for surface activation prior to the gluing of composites:

- Composite/composite joints.

- Hybrid composite/titanium joints.

To do this, Labcyp studies properties such as:

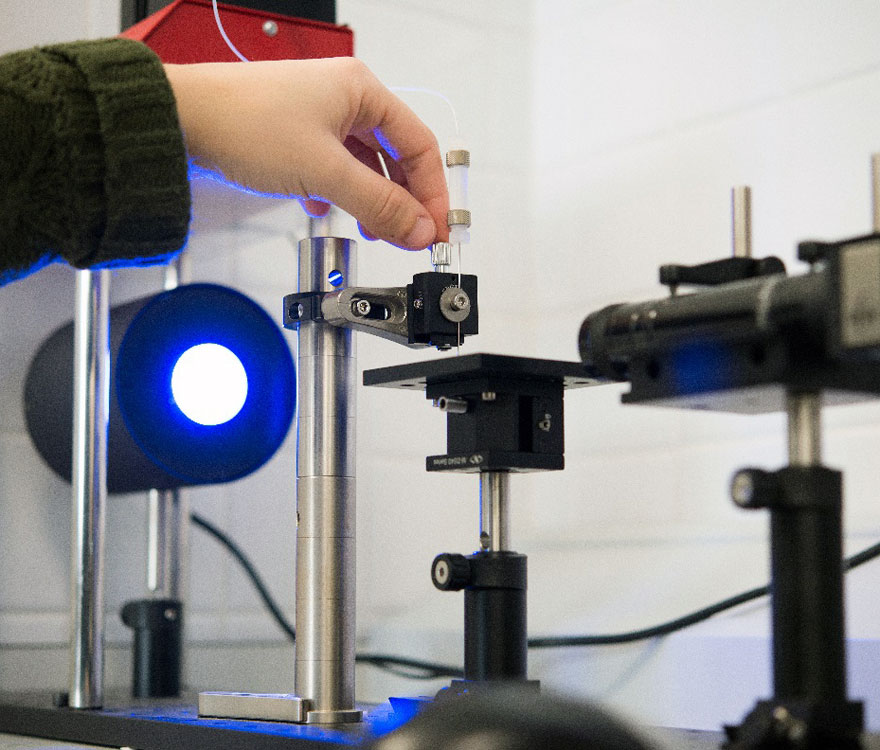

- surface energy.

- surface composition.

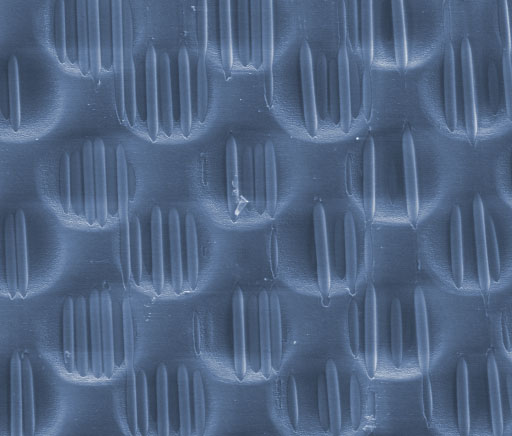

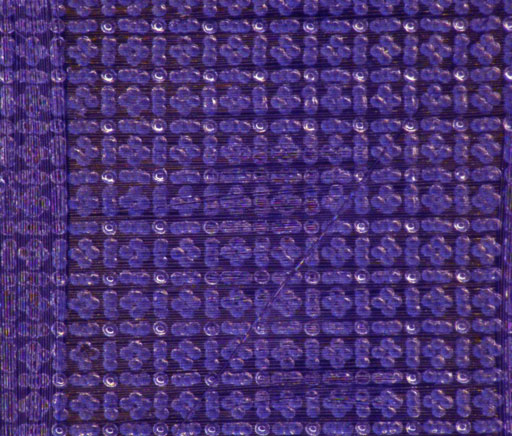

- microstructure.

- tenacity to intralaminar fracture.

- simple cut.

Línea de investigación 03

Surface processing of CFRPs.

The adhesive bonding of CFRP elements to develop complex aircraft structures includes stages with high manual workloads, such as surface activation prior to gluing. It is therefore desirable to find processes that increase the level of automation of these processes.

In this line of research, a pulsed UV laser is used to carry out the surface activation process prior to the gluing of carbon fibre elements used in aeronautics.

A Trumpf TruMark 6350 pulsed laser is used which emits at 335nm with a power of 5W.

Publicaciones

Estas son algunas de las publicaciones de los miembros del Grupo de Protección y Corrosión relacionadas con esta línea de investigación.

Puedes acceder a los contenidos íntegros de las publicaciones a través de su correspondiente enlace de ResearchGate.