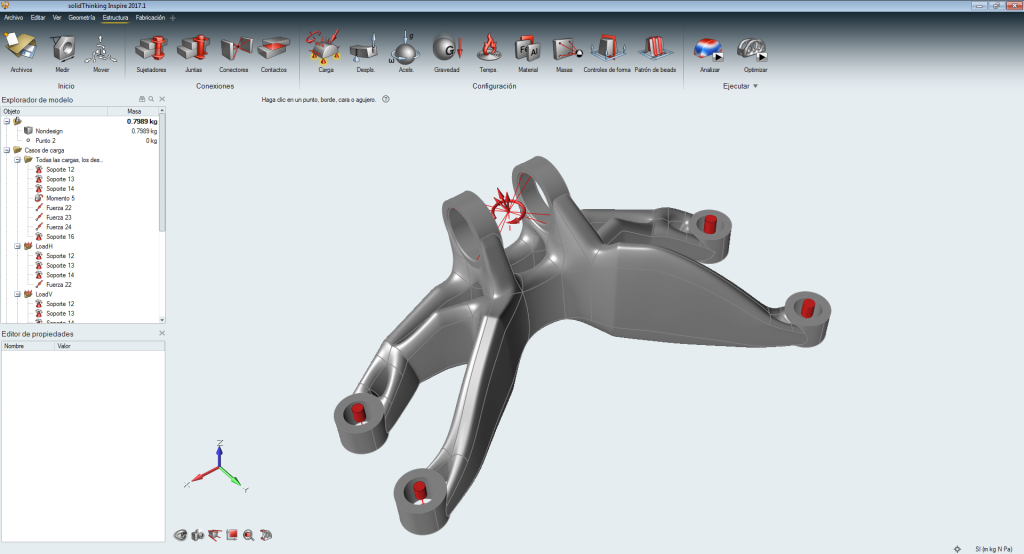

Optimisation, manufacturing, post-processing and characterisation of parts manufactured with the additive manufacturing tecnology, Direct Metal Laser Sintering.

Since 2015, Labcyp has been working on topological optimization, manufacturing, surface improvement and characterization of parts manufactured by direct laser sintering of Ti alloys, Al alloys and stainless steel.

We are currently focused on the optimization, manufacture and study of chemical and mechanical properties of parts made of stainless steel AISI 15-5PH and scalmalloy, for example:

- Roughness.

- Material porosity.

- Corrosion resistance.

- Tensile strength.

Línea de investigación 06

Additive manufacturing using DMLS

For the development of this line of research the group counts on:

CAD design software, topological optimization and analysis of mechanical properties of parts to be manufactured using DMLS.

EOS M290 DMLS machine with EOS license to work with stainless steel alloys AISI 15-5PH, Ti6Al4V, AlSi10Mg and Scalmalloy. Furthermore, we are qualified to work with Scalmalloy

Sandblasting equipment and electropolishing systems for surface improvement of parts manufactured by DMLS.

Electronic and optical microscopy equipment for the determination of porosity of parts manufactured by DMLS.

Publications

These are some of the publications of the members of the Protection and Corrosion Group related to this line of research.

You can access the complete contents of the publications through the corresponding link on ResearchGate.